General Information

Common design weakness in the cabin and interior design of all BMWs produced between 2011 and 2016

If you are one of the fans of BMW or you are planning to buy a BMW model between 2011 and 2016, there are a series of acute and serious weaknesses in the interior design and plastic and leather parts used in these cars. be a slave In this article, we will examine all the weaknesses together and we will also examine why an automobile company like BMW, which has always been one of the top 10 brands in the automobile industry, has suffered such a fatal error.

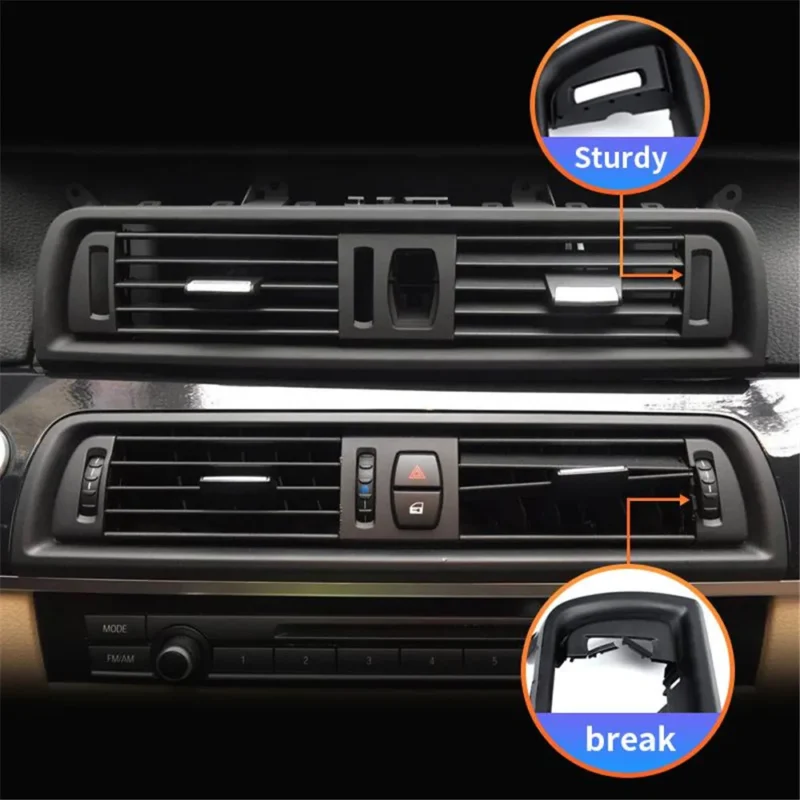

BMW Interior Weakness

The use of poor material in BMW spare parts is strange, but really, why did the engineers and designers not be careful enough in choosing the decorative items inside the BMW cabin? We will show you strange incidents and breakdowns that you will definitely need to buy spare parts for.

Door Handler

One of the most common breakdowns is the interior leather handles in BMW that melt. It is really a special and strange problem that causes nerves and the color of melted leather can make your whole car dirty. All handles face this problem after some time of use. BMW 520, 528 and 530 are flag bearers

Why low quality in BMW

You must have heard that some factories, after production, if the car encounters basic problems that violate the standard or is dangerous, they ask the owners to take the car to the dealers and replace the dangerous part with a new model. It is also completely free. But this usually happens in spare parts and I have never seen automobile manufacturers recall cars for defects and damage to leather and plastic parts inside the cabin.

But it is unlikely that problems like this will occur from a car manufacturer with high standards like BMW. In the following, we will examine why BMW has this fundamental problem.

1. Cost Reduction and Cheaper Production:

To cut production expenses, some businesses could opt for speedier or less expensive materials, but this could mean a drop in quality.

I doubt that the reason for the poor quality of the interior leather and plastic parts used by BMW was due to cost savings, because BMW cars are not cheap anyway.

2. Continuity of Technology and Engineering:

Poor engineering and technological continuity can occasionally result in problems with quality. A company’s goods may suffer in quality if it does not use cutting-edge technologies and maintain its production procedures up to date.

Again, BMW is one of the pioneers of technology in the field of automobile manufacturing, did the research and development team at BMW not really test the quality of the required materials before use. Of course, nothing is unlikely, but I don’t think so.

3. Misuse of the Supply Chain

4. Issues in the Production Process

5. Changes in Management

Final Words

With all these shortcomings in BMW cars produced between 2011 and 2016, it doesn’t matter which room it is from BMW F25, BMW F26, BMW F30, BMW F10, BMW F32 Other models have these common problems.

The least BMW could do is apologize to its customers for this shortcoming and explain the mistake with a postcard. But even this company did not post an announcement on its official website. It should be noted that in newer models, these problems have decreased and they have tried to solve them.